Forklift training

Fully accredited and quality assured forklift

operator training for businesses.

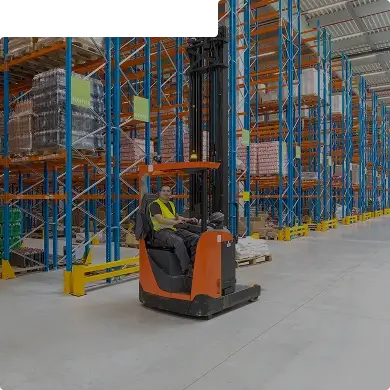

Our certified, on and off-site counterbalance and reach forklift training courses equip your learners with everything they need to safely and effectively operate within a warehouse environment.

Our courses

We offer counterbalance and reach forklift operator license in novice, skilled operator, and refresher levels.

Counterbalance

training

Our counterbalance training combine both theory and practical exercises in accordance with health and safety executive guidelines.

Training Levels: Novice, skilled and refresher

Course Duration: 3, 4 and 5 days

A counterbalance forklift is a truck that uses a counterweight at the rear to balance the weight of the load being lifted at the front. This design allows the forklift to drive up close to the load and extend its forks to lift it. They are the most common type of forklift in the world and are used in many different settings, including: Warehouses, Factories, Distribution centres, Dockyards, and Construction sites.

Reach training

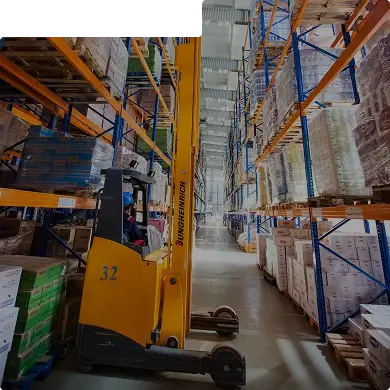

Our reach operator training course covers theoretical and practical examinations, vehicle loading and offloading, refuelling and recharging procedures including battery handling and load handling skills.

Training Levels: Novice, skilled and refresher

Course Duration: 3, 4 and 5 days

Reach trucks are forklifts typically used in narrow aisle warehouse environments. They are designed to have two outer legs that help distribute the load and a single set of wheels at the back. The wheels are below the operator, which helps create a tighter turn radius. This allows operators to navigate smaller spaces, and still be able to reach higher racking.

Our courses

We offer counterbalance and reach forklift operator license in novice, skilled operator, and refresher levels.

Counterbalance

training

Our counterbalance training combine both theory and practical exercises in accordance with health and safety executive guidelines.

Training Levels: Novice, skilled and refresher

Course Duration: 3, 4 and 5 days

A counterbalance forklift is a truck that uses a counterweight at the rear to balance the weight of the load being lifted at the front. This design allows the forklift to drive up close to the load and extend its forks to lift it. They are the most common type of forklift in the world and are used in many different settings, including: Warehouses, Factories, Distribution Centres, Dockyards, and Construction sites.

Reach training

Our reach operator training course covers theoretical and practical examinations, vehicle loading and offloading, refuelling and recharging procedures including battery handling and load handling skills.

Training Levels: Novice, skilled and refresher

Course Duration: 3, 4 and 5 days

Reach trucks are forklifts typically used in narrow aisle warehouse environments. They are designed to have two outer legs that help distribute the load and a single set of wheels at the back. The wheels are below the operator, which helps create a tighter turn radius. This allows operators to navigate smaller spaces, and still be able to reach higher racking.

All our training is accredited by RTITB, ITSAAR, ALLMI, NPORS or AITT.

What is involved in the forklift training course?

Hazard awareness techniques

- Identifying and minimising dangers to both the operator and those in the surrounding area.

Forklift truck introduction

- Overview of the specific forklift truck type to be used.

- Daily pre-use inspection procedures.

- Maintenance principles to be followed before operating the truck.

Basic forklift operation

- Starting, moving, and stopping the truck.

- Manoeuvring in both open and confined areas.

Safety education

- Training on best practices for forklift operation.

Vehicle-specific fuelling requirements

- Proper care for battery-powered, LPG, and diesel trucks.

Handling pallets

- Managing unladen and laden pallets.

- Stacking and de-stacking at various heights.

- Emphasis on correct loading and unloading procedures.

Hydraulic control operations

- Operation of hydraulic controls.

- Assessing weight and stability factors during lifting and moving.

Knowledge and competency assessment

- A theory test on lift truck knowledge.

- A practical test to assess operating skills and operator competency.

Additional courses

Frequently asked questions

What is the difference between counterbalance and reach forklift training?

Counterbalance forklifts are designed for outdoor use or in areas with large, open spaces. The operator balances the weight of the load at the front with the weight of the forklift at the rear. Reach forklifts, on the other hand, are used in narrower spaces, such as warehouses, and are designed for handling pallets at high heights with extended reach capabilities. Both types of forklifts require specific training to ensure safe and efficient operation.

Why is forklift certification important for businesses?

Forklift certification ensures that employees can operate forklifts safely, reducing the risk of accidents and improving overall efficiency. It also helps businesses stay compliant with regulations, like the Provision and Use of Work Equipment Regulations (PUWER) in the UK, which require operators to be adequately trained. Proper certification can prevent costly accidents and legal issues due to non-compliance.

How long does forklift training take, and what is included?

The length of training depends on the type of forklift, the learner to trainer ratio and the experience level of the operator. Typically, new operators require 3-5 days of training, which includes both classroom instruction and hands-on practical experience. The training covers operating techniques, safety protocols, equipment inspections, and handling different loads. Recertification for experienced operators may take 1-2 days.

How often do forklift operators need recertification?

Forklift operators are not required to undergo recertification. Most businesses, however, choose to put their drivers through refresher courses to ensure they are up to date with the latest safety and operating techniques.

Can forklift training be customised for specific business needs?

Yes, training programs can be tailored to the specific requirements of your business. Many of our clients opt for training that focuses on their specific operating environment. In these situations, we provide training at your site. We also tailor training based on particular forklift models, or specific safety protocols relevant to the company’s industry.

How can we help?

Contact us today and a member of our Sales Team will be in touch to understand your needs

or give us a call on 0330 818 8888.